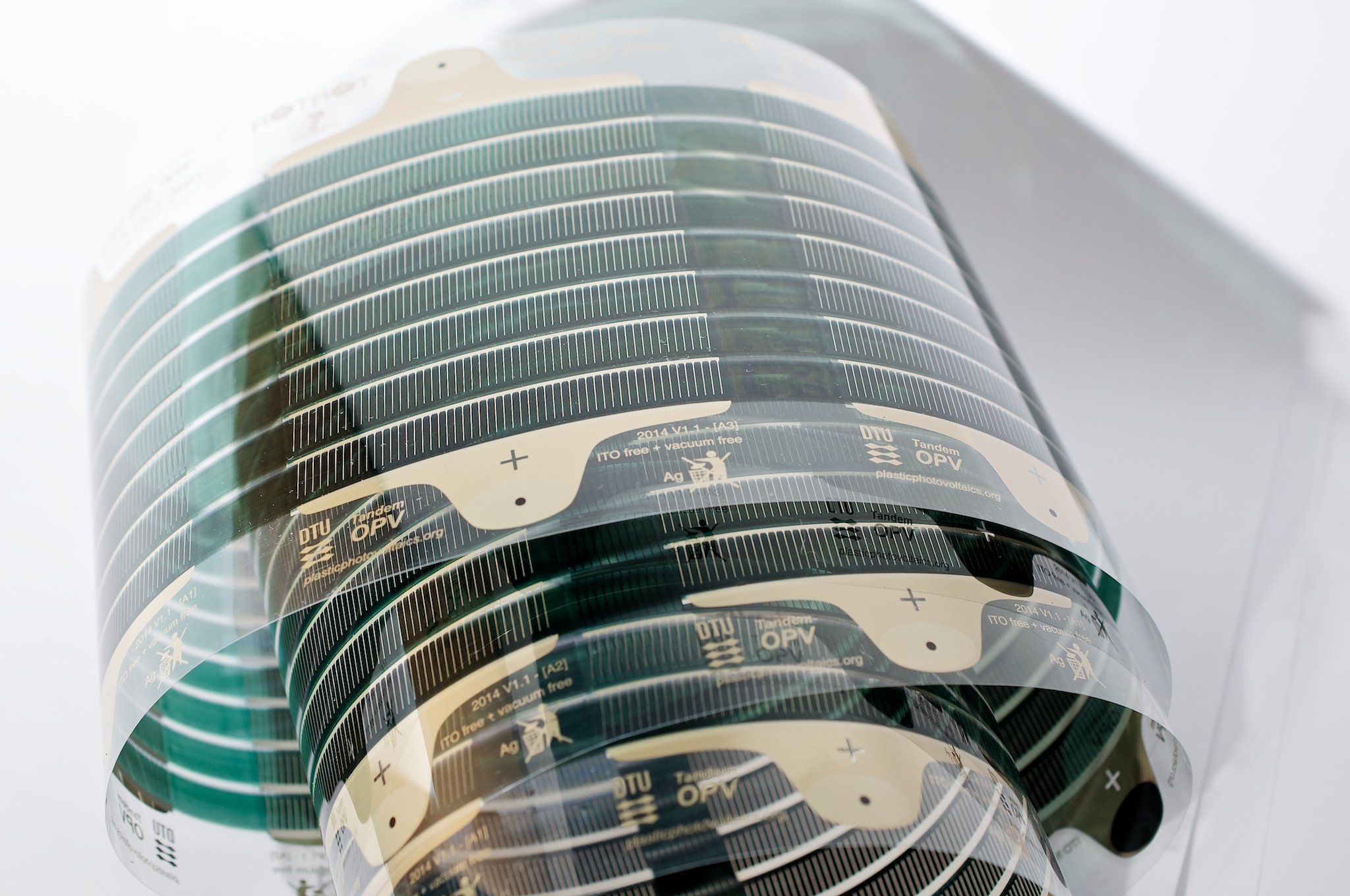

Case: Solceller fremstillet af plastic

Solar cells

DTU Energy

Clean Energy / Future Materials

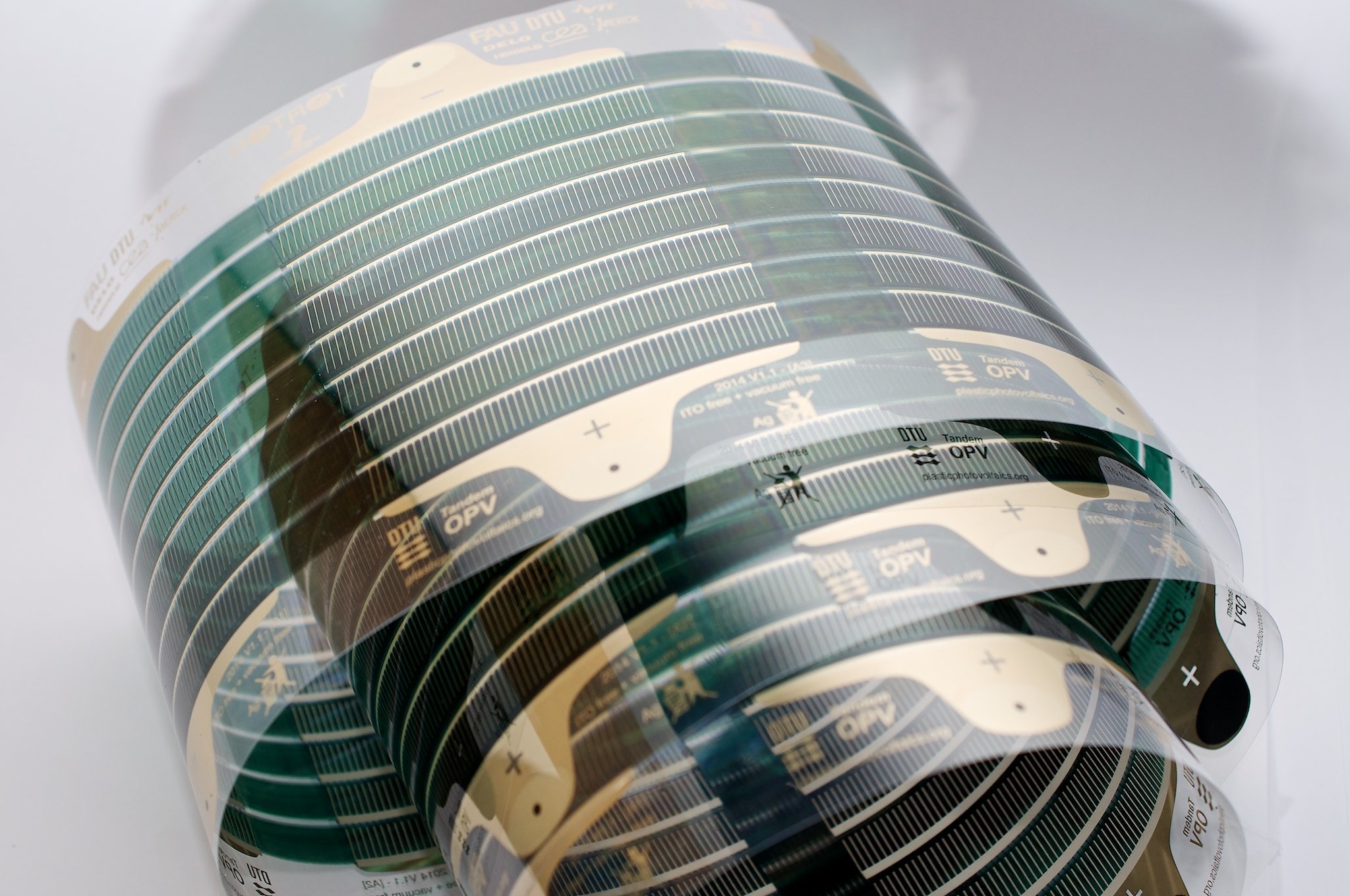

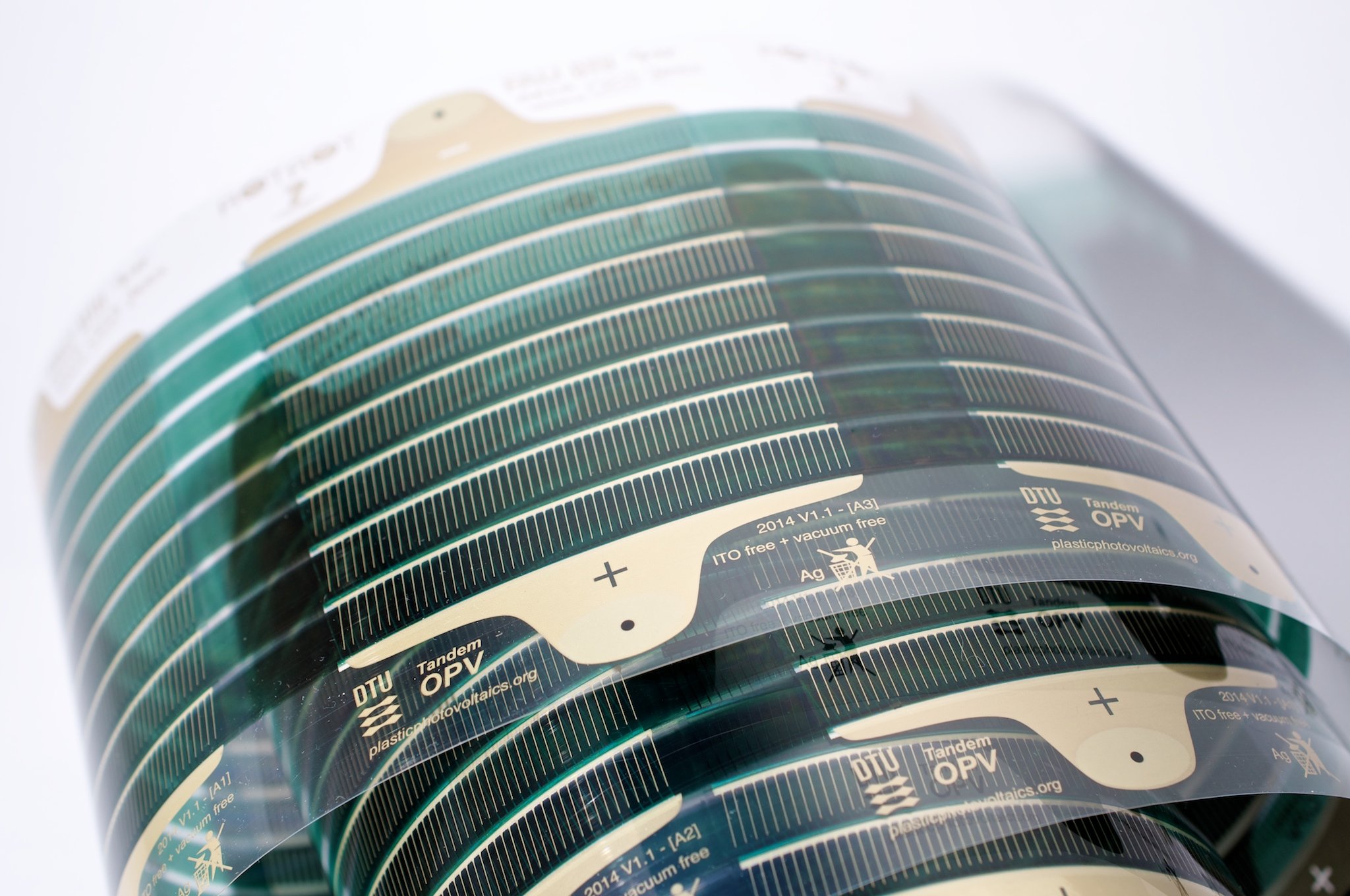

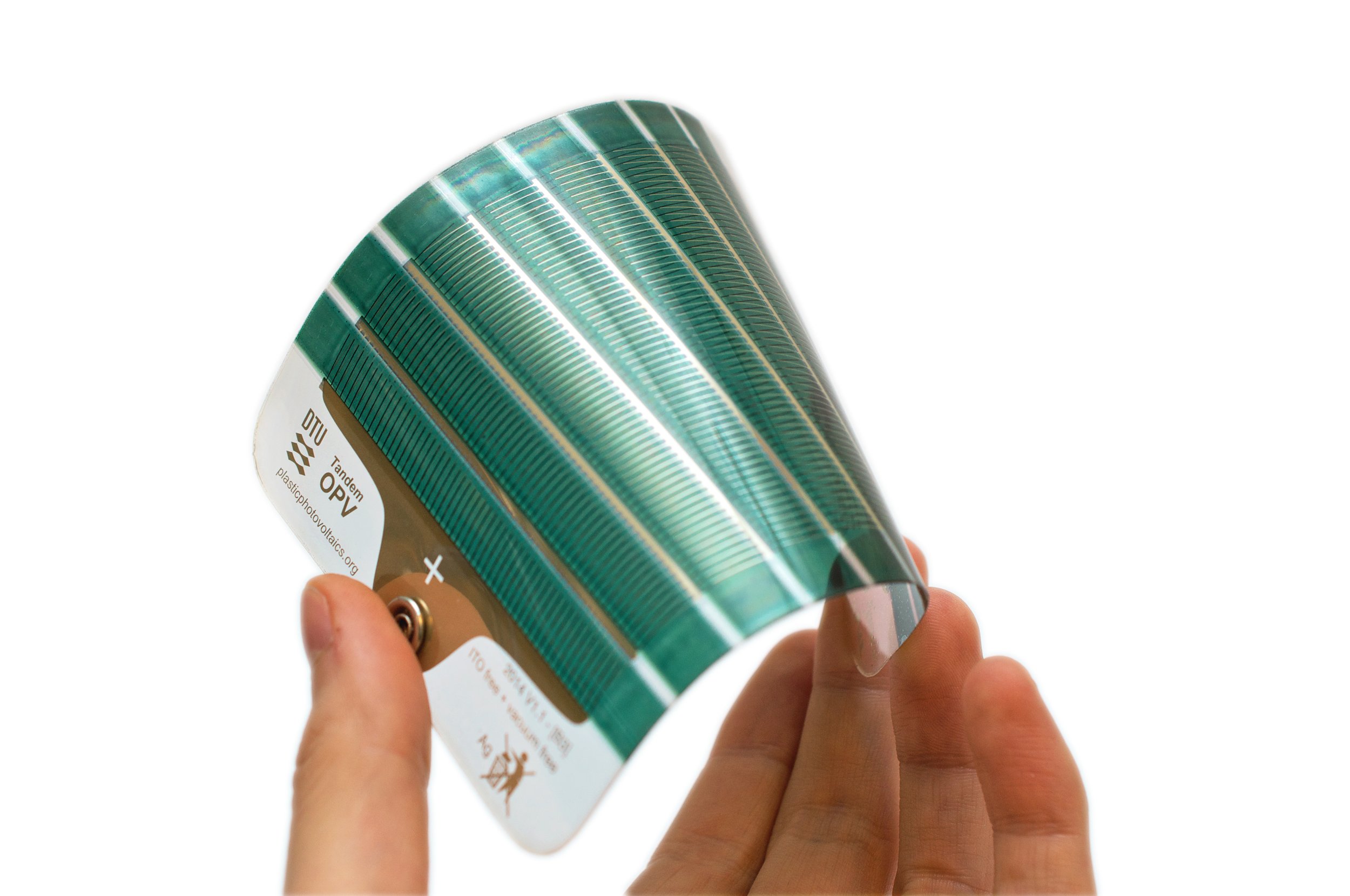

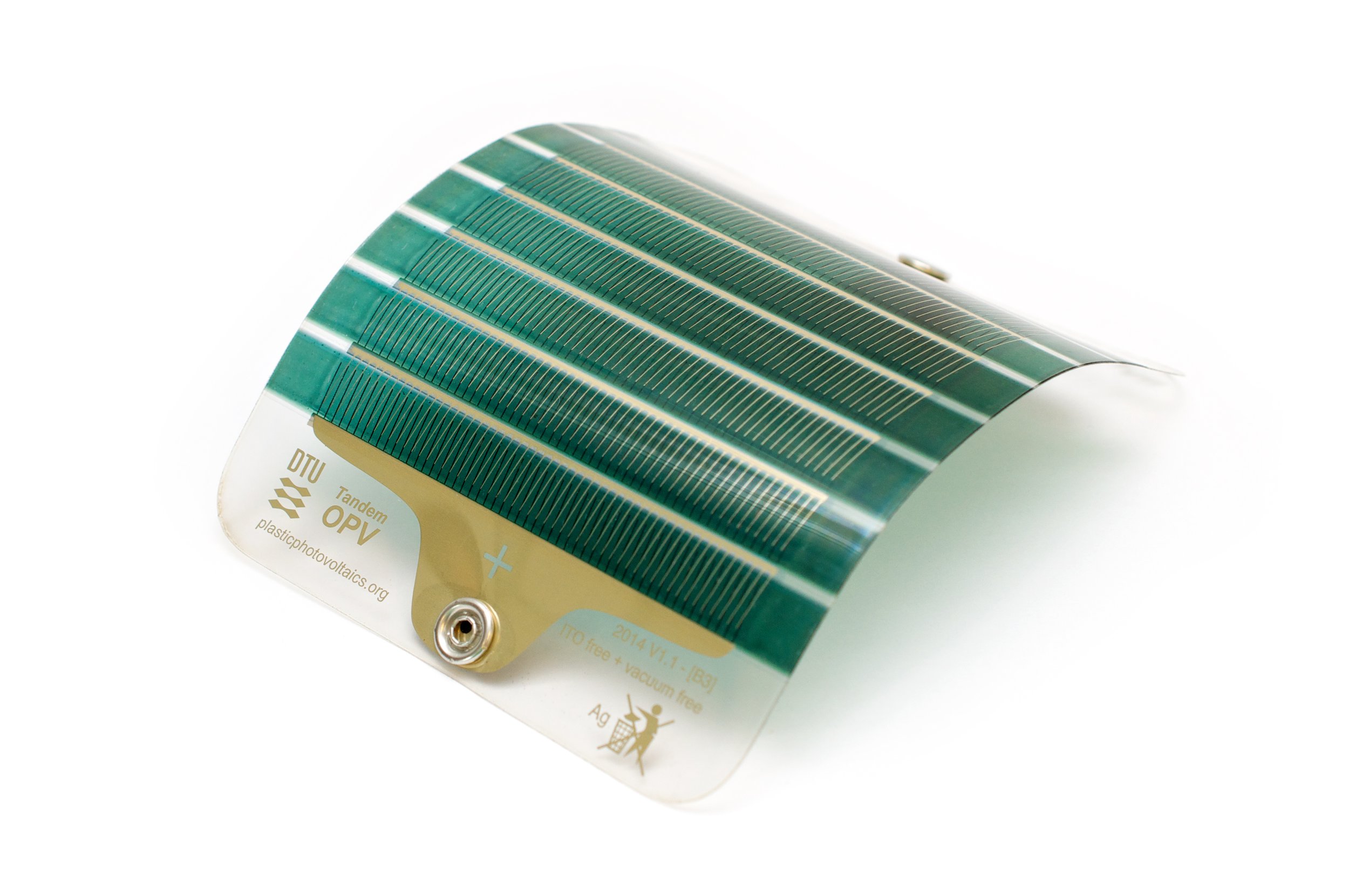

Plastic solar cells have the potential for lowering the manufacturing cost by several orders of magnitude compared to the conventional silicon solar cells. This is because the processing can be done entirely from solution, without requiring high-vacuum or high-temperature steps.

After an intense research effort from 2000, the field of plastic solar cells seemed to be winding down by the end of last decade, as no significant gains in power conversion efficiency were made for several years. This changed dramatically in 2018, when a new class of organic materials were discovered, boosting the power conversion efficiency to values that are comparable to commercial silicon solar cells.

What remains is to achieve this competitive efficiency on large areas of several square meters, and to ensure that this efficiency is stable over time, i.e., at least 10 years. This is now the topic of the research at the forefront of the field, and when this is solved, the technology may conquer certain areas of power production that is currently lacking efficient alternatives: Integration in greenhouses is an obvious application area, where the introduction of a power-generating plastic barrier could justify a higher-value and more robust alternative to the cheap foils that are currently in use, for instance in the “Sea of Plastic” in Almeria in Spain.

Another field is the fast growing “Internet of Things” where a huge environmental challenge is looming, if these billions of devices are to be powered by batteries. Here, plastic solar cells could provide sustainable energy from ambient lighting.

DTU have over the years spun out and/or collaborated with several companies that have specialized in manufacturing of organic solar cells, and the equipment for this, including characterization:

Links: