Case: Family houses insulated with modern insulation

Insulation for the entire building envelope

EPS-branchen & PUR-sektionen

Sustainable Architecture & Construction

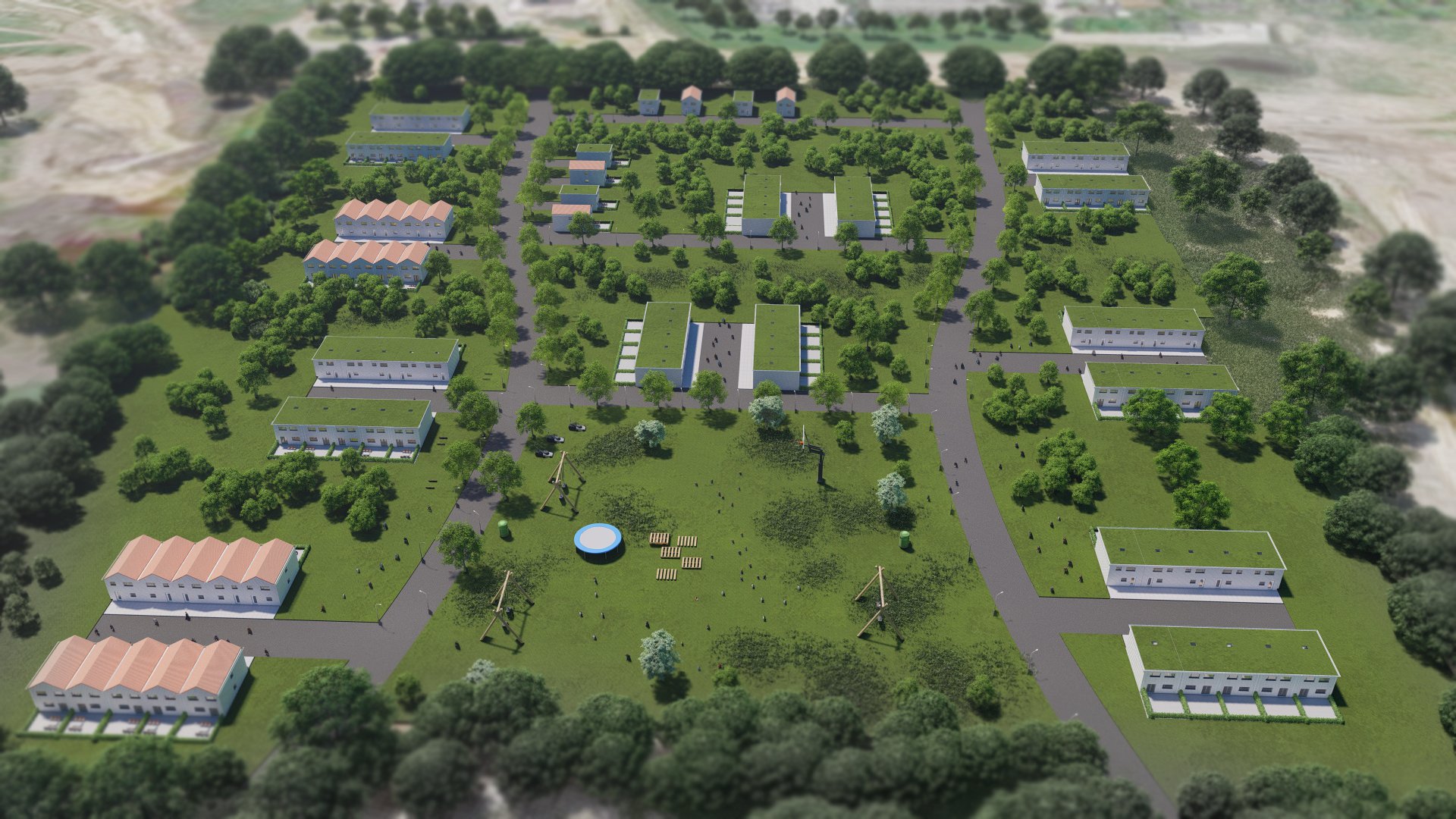

Modern Plastic Insulation allows for aesthetically pleasing, fire safe and sustainable construction. In the Modern Insulation Village you can see how the entire building envelope can be insulated by various uses of modern insulation, in design that comply the strictest fire and climate regulations.

Modern insulation materials are becoming increasingly popular in construction. The materials allow for a high level of design flexibility, while their performance, durability, low maintenance and light weight all contribute to making them cost-efficient. And often the high insulation values of modern insulation result in lower climate impact, when looking at the actual amount of insulation needed.

Building fire safe and sustainable constructions requires a look at the entire building design and all the materials used in the design. Such a holistic approach improves fire safety and reduces the overall climate impact of the building during construction and over its full life span. In taking this into consideration, it becomes clear why, Modern Insulation is fully compatible with sustainable, cost-efficient and fire safe building designs.

To further elaborate on this we have designed the Modern Insulation Village, where you can learn more about how EPS and PU Insulation be used in a variety of construction designs.

About Modern Insulation:

EPS (Expanded Polystyrene)

EPS consists of 2% polystyrene, 98% and is 100% recyclable. Seriously versatile, EPS offers the perfect combination of mechanical and physical properties, including dimensional stability, permanent R-value and inherent water resistance and compressive strength, as well as offering longevity and sustainable green credentials. Efficient, durable and time-tested for over 60 years, EPS insulation is a purposeful way to meet design specifications and climate protection goals.

PU (POLYURETHANE INSULATION)

Polyurethane is a generic term, which covers a wide range of different formulations and applications derived from a

reaction of diisocyanate with a polyol. The closed cell structure and high crosslinking density of PUR and PIR gives it the characteristics of good heat stability, high compressive strength and excellent insulation properties. PU can achieve a thermal conductivity as low as 0.022 W/m·K. When compared to other materials, a much lower thickness of PU insulation is needed to get the same level of performance.