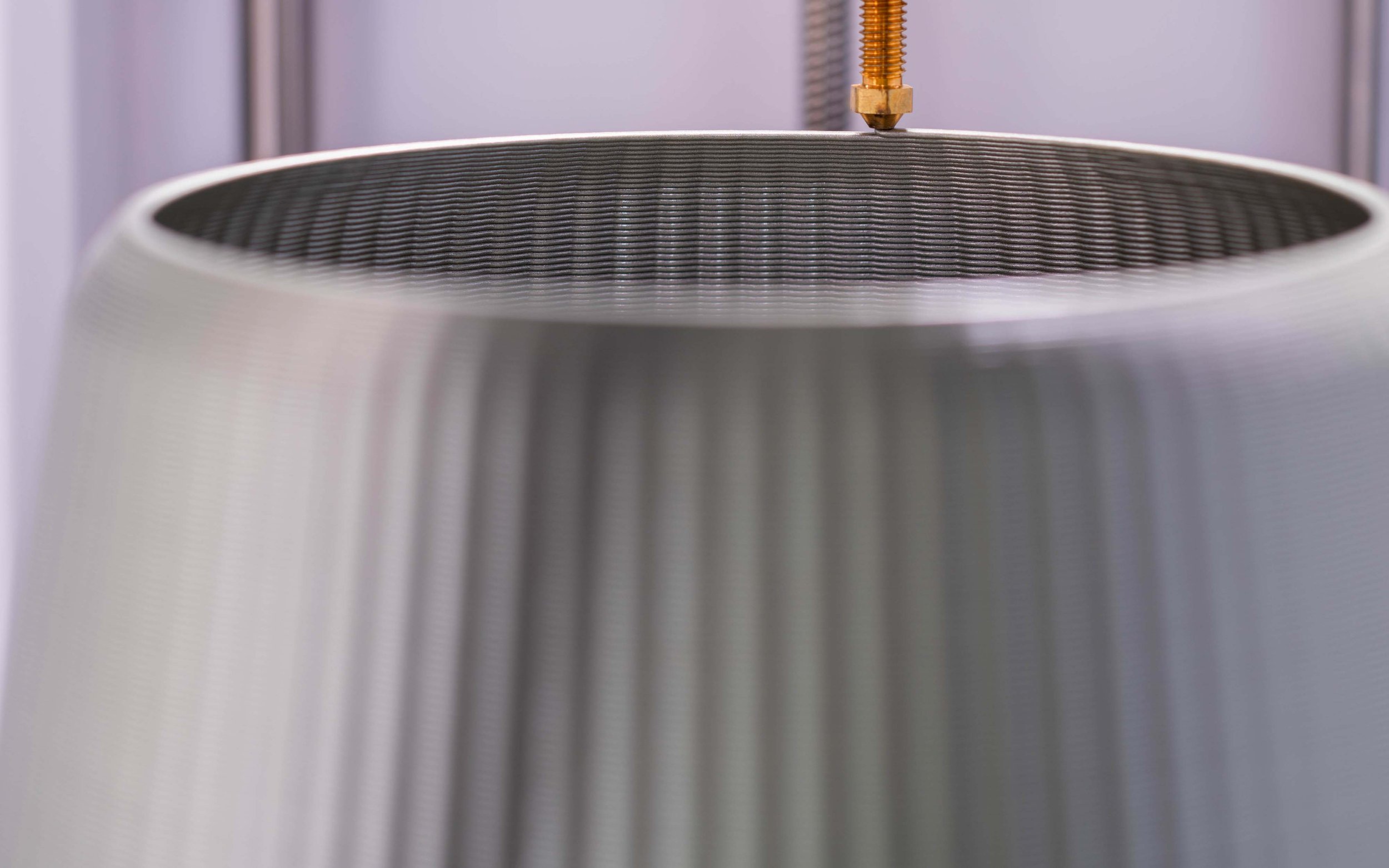

Case: 3D printed lighting

Philips MyCreation

Signify

Beautiful Plastics / Plastic Recycling / Future Materials

3D-printed lighting have the possibility of low enviromental impacts and Signify is aiming to contribute to circular economy, reducing CO2 emssions and eliminate waste with its products.

Signify is on target to produce all printed parts with at least 55% recycled or mass balanced bio-circular plastics. The percentage is higher when using recycled polycarbonate from post-industrial or post-consumer waste streams. Signify also produce lamps which incorporates recycled fishing nets.

Bio-circular raw materials are materials from ISCC Plus-certified waste streams and residues, such as tall oil from the wood processing industry and used cooking oil.

3D technology allows the creation of shapes not possible with traditional production. As a result, the products consist of fewer components. It is not necessary to assemble parts with glue or other non-reversible methods, and the use of screws is minimised. 3D printed luminaires are designed for easy disassembly. The merging of multiple components into one single component makes it easier to assemble and disassemble the products.

A considerable amount of carbon emissions is linked to the material extraction and manufactuiring. Signify has eliminated long supply chains – sourcing parts from suppliers and storing those in a warehouse – in favour of in-house printing. With shorter supply lines and lighter material, carbon emissions can be lowered.

The transport of the material also contributes to carbon emissions. 3D printed parts in polycarbonate are light, making it more possible to use less fuel in transportation resulting in less carbon emissions.

Printing on-demand

With shorter supply lines and ultra-short production times, Signify can make last-minute production decisions. By printing on-demand, they don’t have stock of unsold products. Fishing nets constitues alot of the plastic in the ocean. and with 4,5 meters of fishing nets, Signify can print one luminaire. As part of the 3D printing production process, Signify recycle in-house, re-using waste such as rejected parts that didn’t pass the quality control. They re-use these as base material to print new products.

Link: